Copper plate

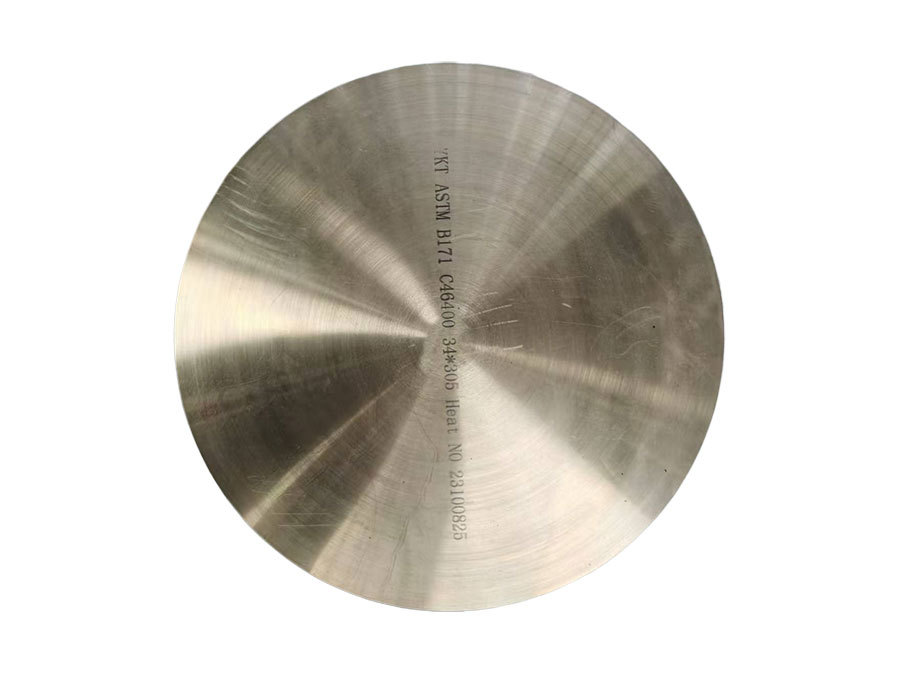

C46400 brass round plate is a high-performance copper alloy material!

Key words:

Copper plate

Classification:

Product Description

Brand |

Variety |

Status |

Specification (mm) |

Main characteristics or performance parameters |

Main direction of use |

Executive standards |

||

Thickness |

Width |

Length |

||||||

T2, T2 conductive TU1, TU2, TP1, TP2, C1100 C10200 |

hot rolled plate |

R |

4~8 |

600~2000 |

≤ 5000 |

When thickness = 4~14mm, Rm ≥ 195Mpa A11.3 ≥ 30% |

Wide range of general use |

GB/T2040-2008 C10200, C1100 Negotiation |

>8~60 |

100~3000 |

≤ 6000 |

||||||

>60~150 |

200~3000 |

≤ 6000 |

Not for performance |

Q/LT001-92 |

||||

cold rolled sheet |

M, Y4, Y2, Y, T |

0.3~0.5 |

≤ 600 |

≤ 2000 |

M state: Rm ≥ 205Mpa A11.3 ≥ 30%; Y4 state: Rm = 215 ~ 275Mpa A11.3 ≥ 25%; Y2 state: Rm = 245 ~ 345Mpa A11.3 ≥ 8%; T state: Rm ≥ 350Mpa |

GB/T2040-2008 C10200, C1100 Negotiation |

||

>0.5~3.0 |

≤ 1020 |

≤ 3000 |

||||||

>3.0~12 |

≤ 3000 |

≤ 6000 |

||||||

T2 Guide |

copper conductive plate |

R |

20~50 |

100~650 |

≤ 8000 |

See standard for high conductivity, tensile force, hardness and bending performance |

Smelting, electrochemical, electroplating and other industries to manufacture conductive bus |

GB/T2529-2005 |

M, Y8, Y2, Y |

4~20 |

100~650 |

≤ 8000 |

|||||

T2 |

Special pure copper plate |

M |

0.3~0.5 |

350~610 |

1000~2000 |

Rm≥205mpa a11.3 ≥ 42%; See standard for cupping and grain size |

|

GJB1139-91 |

>0.5~3.0 |

≤ 1020 |

450~3000 |

||||||

>3.0~10 |

≤ 1000 |

≤ 2000 |

||||||

T2A |

Y |

4.0~8.0 |

200~1000 |

400~2000 |

Rm = 295 ~ 355Mpa A11.3 ≥ 5%; see standard for grain size |

|||

TAg0.1 |

silver copper hot rolled plate |

R |

4~8 |

600~2000 |

1000~5000 |

When thickness = 4~14mm, Rm≥ 195Mpa, A11.3 ≥ 30% |

Crystallizer, etc. |

Q/LT002-92 |

>8~60 |

600~3000 |

1000~6000 |

||||||

>60~150 |

600~2500 |

1000~4000 |

||||||

TU1 TU2 C10200 LC1011 |

Oxygen-free copper plate |

And 、 Y2 、 M |

0.3~0.5 |

≤ 600 |

≤ 2000 |

M state: Rm 195 ~ 260Mpa A11.3 ≥ 40%; Y2 state: Rm 245 ~ 315Mpa A11.3 ≥ 15%; Y state: Rm≥ 275Mpa See the standard for conductivity and oxygen content. |

Electronics Industry Sector |

GB/T14594-2005 C10200, LC1011 Negotiation |

>0.5~3.0 |

≤ 1020 |

≤ 3000 |

||||||

>3.0~10 |

≤ 3000 |

≤ 6000 |

||||||

TU2 |

For cooling wall Oxygen-free copper plate |

R |

75~150 |

600~1590 |

1400~3600 |

high conductivity |

blast furnace steelmaking |

Enterprise Standard |

LC1100 |

electronic tough copper |

Y 、 Y2 、 Y4 、 M |

0.5~2.5 |

≤ 1000 |

≤ 2000 |

See standard |

Electronic Materials |

Enterprise Standard |

T2 |

copper door plate |

Y |

0.5~2.5 |

600~1000 |

≤ 3000 |

Tensile strength ≥ 300MPa, no crack at 90 ° bending |

Copper door |

Enterprise Standard |

Note: Non-standard range products can be negotiated. |

||||||||

Brand |

Variety |

Status |

Specification (mm) |

Main characteristics or performance parameters |

Main direction of use |

Executive standards |

||

Thickness |

Width |

Length |

||||||

T2, T2 conductive TU1, TU2, TP1, TP2, C1100 C10200 |

hot rolled plate |

R |

4~8 |

600~2000 |

≤ 5000 |

When thickness = 4~14mm, Rm ≥ 195Mpa A11.3 ≥ 30% |

Wide range of general use |

GB/T2040-2008 C10200, C1100 Negotiation |

>8~60 |

100~3000 |

≤ 6000 |

||||||

>60~150 |

200~3000 |

≤ 6000 |

Not for performance |

Q/LT001-92 |

||||

cold rolled sheet |

M, Y4, Y2, Y, T |

0.3~0.5 |

≤ 600 |

≤ 2000 |

M state: Rm ≥ 205Mpa A11.3 ≥ 30%; Y4 state: Rm = 215 ~ 275Mpa A11.3 ≥ 25%; Y2 state: Rm = 245 ~ 345Mpa A11.3 ≥ 8%; T state: Rm ≥ 350Mpa |

GB/T2040-2008 C10200, C1100 Negotiation |

||

>0.5~3.0 |

≤ 1020 |

≤ 3000 |

||||||

>3.0~12 |

≤ 3000 |

≤ 6000 |

||||||

T2 Guide |

copper conductive plate |

R |

20~50 |

100~650 |

≤ 8000 |

See standard for high conductivity, tensile force, hardness and bending performance |

Smelting, electrochemical, electroplating and other industries to manufacture conductive bus |

GB/T2529-2005 |

M, Y8, Y2, Y |

4~20 |

100~650 |

≤ 8000 |

|||||

T2 |

Special pure copper plate |

M |

0.3~0.5 |

350~610 |

1000~2000 |

Rm≥205mpa a11.3 ≥ 42%; See standard for cupping and grain size |

|

GJB1139-91 |

>0.5~3.0 |

≤ 1020 |

450~3000 |

||||||

>3.0~10 |

≤ 1000 |

≤ 2000 |

||||||

T2A |

Y |

4.0~8.0 |

200~1000 |

400~2000 |

Rm = 295 ~ 355Mpa A11.3 ≥ 5%; see standard for grain size |

|||

TAg0.1 |

silver copper hot rolled plate |

R |

4~8 |

600~2000 |

1000~5000 |

When thickness = 4~14mm, Rm≥ 195Mpa, A11.3 ≥ 30% |

Crystallizer, etc. |

Q/LT002-92 |

>8~60 |

600~3000 |

1000~6000 |

||||||

>60~150 |

600~2500 |

1000~4000 |

||||||

TU1 TU2 C10200 LC1011 |

Oxygen-free copper plate |

And 、 Y2 、 M |

0.3~0.5 |

≤ 600 |

≤ 2000 |

M state: Rm 195 ~ 260Mpa A11.3 ≥ 40%; Y2 state: Rm 245 ~ 315Mpa A11.3 ≥ 15%; Y state: Rm≥ 275Mpa See the standard for conductivity and oxygen content. |

Electronics Industry Sector |

GB/T14594-2005 C10200, LC1011 Negotiation |

>0.5~3.0 |

≤ 1020 |

≤ 3000 |

||||||

>3.0~10 |

≤ 3000 |

≤ 6000 |

||||||

TU2 |

For cooling wall Oxygen-free copper plate |

R |

75~150 |

600~1590 |

1400~3600 |

high conductivity |

blast furnace steelmaking |

Enterprise Standard |

LC1100 |

electronic tough copper |

Y 、 Y2 、 Y4 、 M |

0.5~2.5 |

≤ 1000 |

≤ 2000 |

See standard |

Electronic Materials |

Enterprise Standard |

T2 |

copper door plate |

Y |

0.5~2.5 |

600~1000 |

≤ 3000 |

Tensile strength ≥ 300MPa, no crack at 90 ° bending |

Copper door |

Enterprise Standard |

Note: Non-standard range products can be negotiated. |

||||||||

Related Products